Intense UV pulses fully sterilize clear-packed clear liquids:

It was proven with our PL system by Baxter Corp. on UV resistant spores of B. Pumilos.

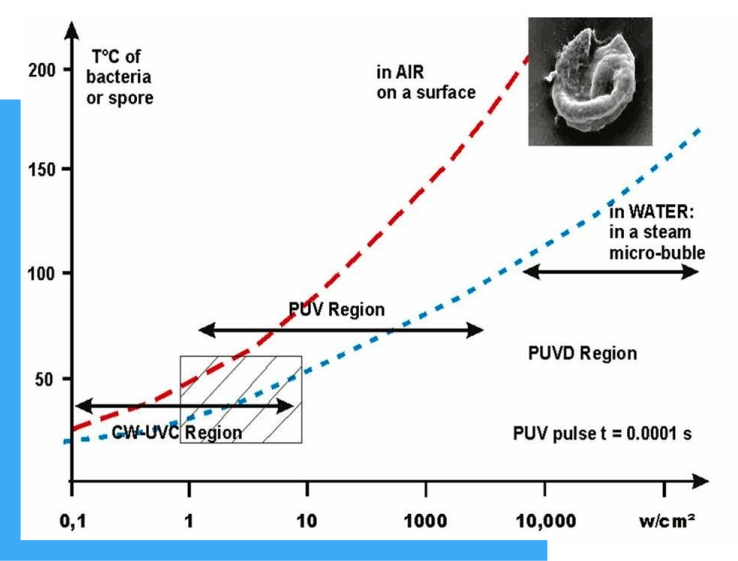

Clarifications: The effectiveness of Pulsed UV light increases with its power from identical to the continuous UVC light by low pressure Mercury vapor lamps to turning on accelerated

DNA damages possible only for the intense UV pulses. Further right on the power scale in w/cm² starts the PUVD region where the applied power of UV and also of the visible light pulses physically disintegrate bacteria and spores.

For second and third processes to happen, UV and light pulses have to be very short, intense and rapid. These conditions were first described and then proven in works of Dr. Alex Wekhof in 1990´s years and got Worldwide following: see our publications and about us in links below.

It makes it possible to sterilize vaccines in vials.

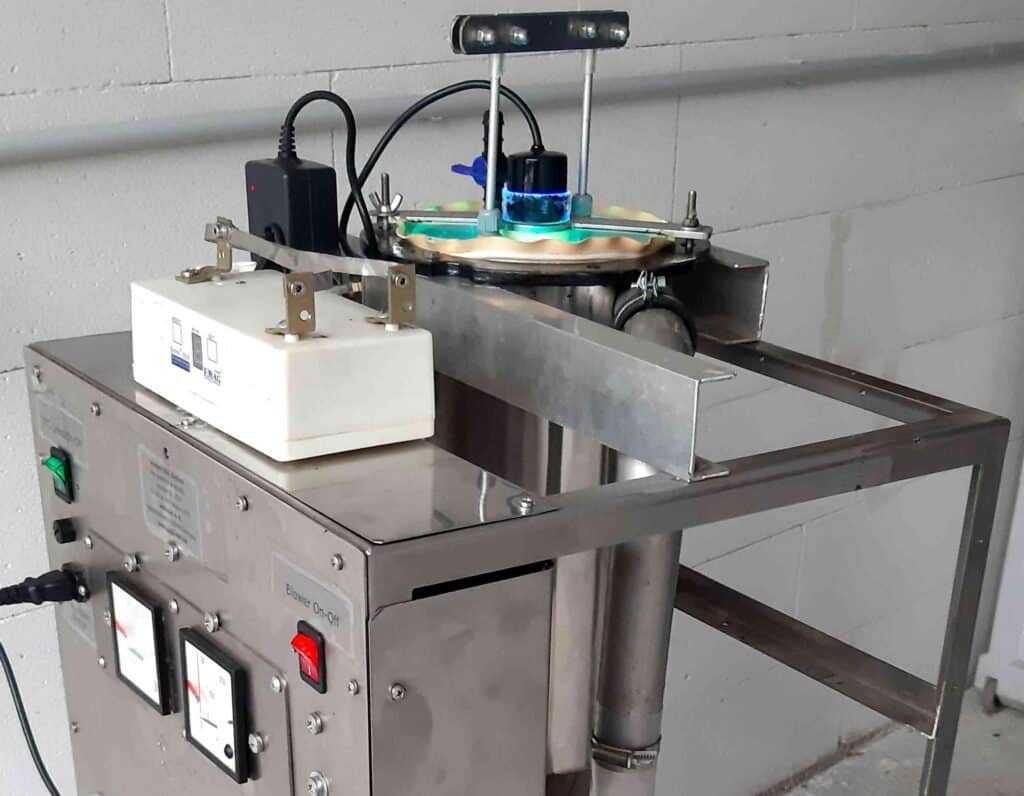

Wek-tec offers to check sterilization

of your products with our PUV R&D systems:

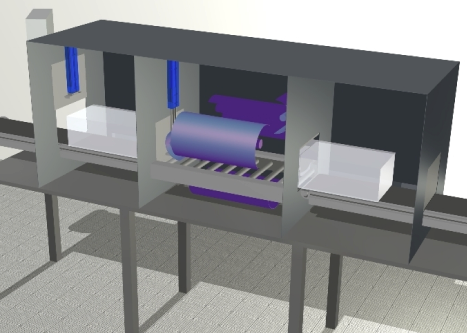

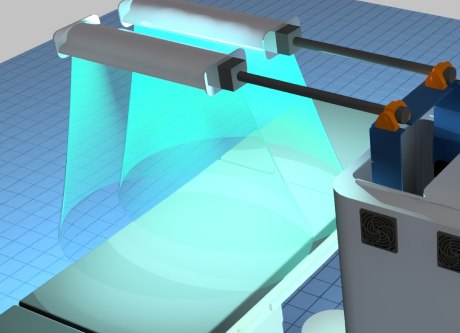

Evaluation data obtained on these two versatile R&D systems with Intense Pulse UV lamps can be scaled up to construct PUV tunnels for packaged foods as below on the left or to sterilize surfaces and air in in hospitals, office rooms etc. as on the right. Designs of these two PUV installations are ready for customization, while a few similar were sold.

NON-INVASIVE STERILIZATION by Strong Pulsed Electrical Fields

of various liquids and creams

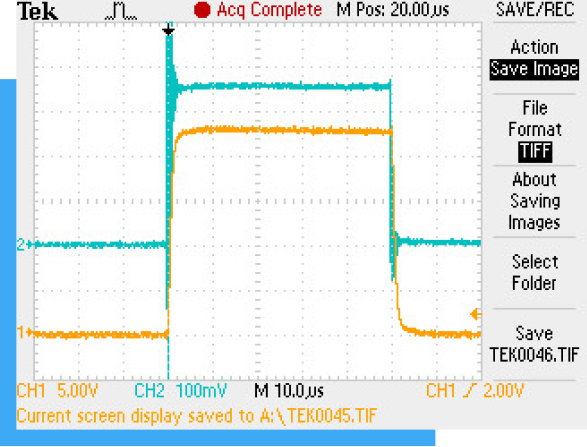

While keeping unchanged its properties with our scalable pilot system and its unique set of very broad positive pulses with durations 2,5µs to 50µs, repetition rates 4Hz to 500Hz, electrical fields in the PEF chambers 5kV/cm to 50kV/cm.

It can be also used for the PEF assisted extraction of juices and/or cosmetic colours from valuable roots, grass, leaves, etc.

PEF sterilizes by

stretching bacteria up to its ruptures by strong electrical fields 20- 50kV/cm delivered by sharp square pulses: details on both processes.

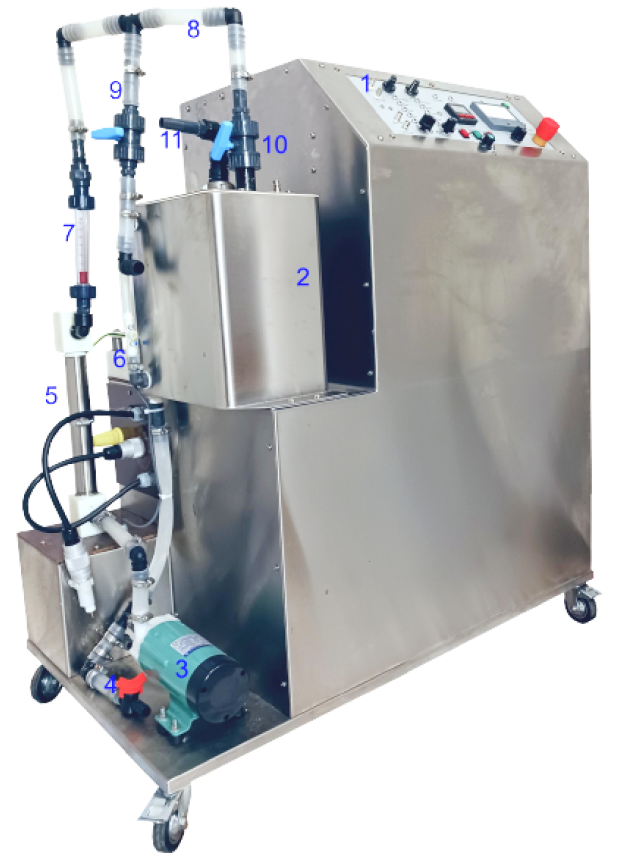

on our the most advanced & versatile PEF pilot:

Its operation is very simple due to its reliable analogue controls lighted by LEDs and covering most of used & published PEF pulse values. Changing between coax & flat PEF chambers takes one min.

It is possible to offer this PEF pilot in two editions:

- For R&D:

PEF coaxial chamber and its batch are for sterilizing juices, etc, and the flat PEF chamber is for creams, honey or for a juice extraction from roots, grass, etc.

- For pilot production:

two PEF in line coaxial chambers operating at the same or at different pulsing parameters selected in tests for the optimal sterilization of juices, wines etc.

We offer this system to develop PEF processes and for sale in food, pharmaceutical and cosmetic industries and to various R&D labs.

Powders sanitation or its modification with UV light

A nutrition powder in this R&D Vortex is moved by a forced Nitrogen rich air flow in the steel cylindrical chamber around a UVC lamp

in order to:

sanitize powder particles by UVC light

or to photo-modify powder properties.

This is the only method to illuminate all powder particles: in its turbulent flow under the UV light. Yet many powders or shreds have physical limitations for higher than :100-reduction in micro-organisms with UV due to its powder particles porosity and/or complex shapes, much of oil content, etc.

At wek-tec we designed a flow-though UV tunnel for sanitizing powders up to 100kg/h. It can be further customized as per evaluation results with customer powders on this Vortex”. This method and our UV tunnel for powders are our IP.